Pavimento - Avio 220 - Contact Conductive

Contact Conductive

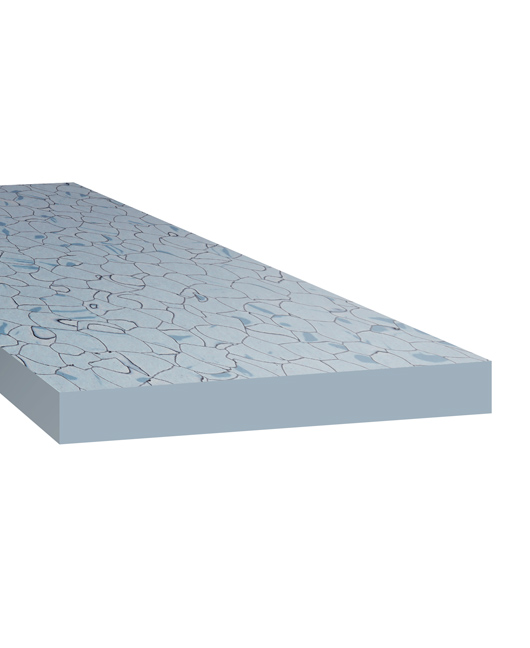

A vinyl floor with CE marking and special construction technique that makes it permanently anti-static, suitable for all spaces where this feature is speciifically required. High resistance to wear and humidity make it even more versatile.

Usage classes and classifications

Composition

Homogeneous blend of vinyl resins, plasticizers, dyes, mineral fillers and specific inorganic additives that make the material conductive. Marbling throughout its thickness. Press processed without the use of calenders. Suitable for heavy traffic.

Type of adhesive: tiles must be laid with conductive adhesive. Earthing: the use of a conductive adhesive allows equalization of electrostatic potential which must then be dispelled towards earth. To this end, we recommend installing a copper strip, also available with a self-adhesive side, (10 x 0.08 mm) in each room/area to form a maximum 12 x 12 m mesh grid. In any case, the copper strip must always be laid following the perimeter of the room (about 10 cm from the wall). One end of the strip must be connected to an earth connection point at a maximum of every 50 m2. Connection points must be opposite each other to better ensure the dispersal of electrostatic charge and must be able to be inspected. Using an electrician for earthing connections, according to relevant safety regulations, is recommended.

Installation instructions: once the subfloor is ready for laying (dry, smooth and cleaned of dust and debris), using a wire beater, trace the grid that the copper strip will follow and begin to lay it by removing the adhesive protection on the back. It is advisable to vigorously press the strip into place and smooth it carefully with a spatula protected by a cloth. Spread the conductive adhesive with a suitable spreader according to the manufacturer's instructions. Joints must be heat-sealed for optimal hygiene or wherever maintenance operations are carried out with a massive water, as well as in any instance where use of a conductive acrylic glue has been chosen. It is good practice to protect the floor after installation with cardboard or polythene sheets in order to avoid damaging the surface during the assembly of furniture and any other subsequent operations.

Electrical tests: after installation the floors must be swept and/or vacuum cleaned to remove any surface residue before then being washed with water and neutral detergent. Tests must be performed no less than 24 hours after completion of installation and cleaning. Carrying out resistance tests towards earth and between two adjacent sections at 5/10 m2 intervals is recommended.

Environmental conditions: a temperature not lower than 18 °C and not higher than 30 °C is required for the acclimatization of the material and during installation.

Floor can be walked on 24 hours after installation. During the first 15 days wash with a wet cloth avoiding the use of excess water. Maintenance treatments must not increase the electrical resistance of the flooring. Therefore, avoid paint treatments or application of greasy waxes. Do not clean with solvents such as tricholorethylene, acetone, etc.